Kostbar. Kompakt. Konzentriert.

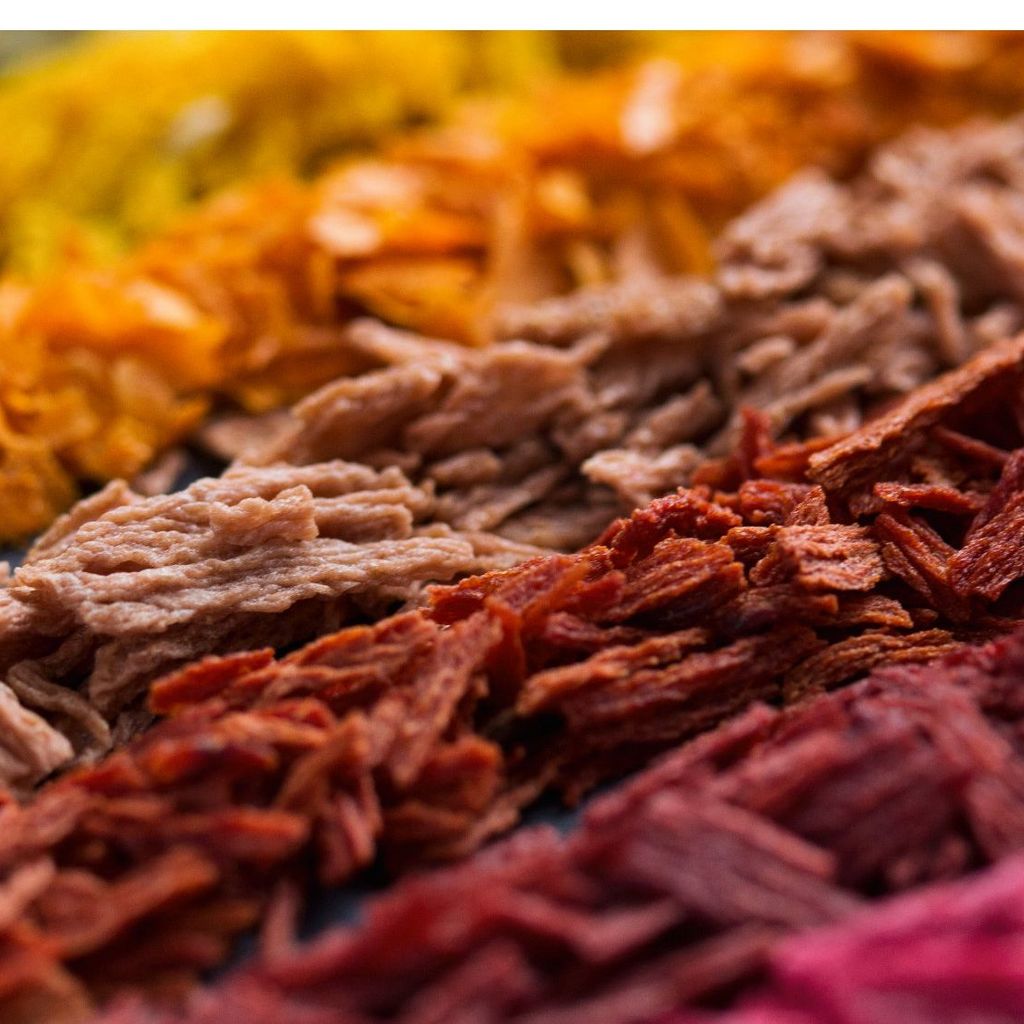

Die walzengetrockneten Produkte von Rabeler erhalten Sie in verschiedenen Feinheitsgraden, passend zu Ihrer Anwendung – von Flocken bis zum Pulver. Dafür stehen Ihnen nahezu alle weltweit verfügbaren Frucht-, Gemüse- und Getreidearten aus konventionellem oder ökologischem Anbau zur Auswahl. Als Alternative zu raffiniertem Zucker, bieten wir außerdem verschiedene natürliche Süßungsmittel in trockener Form an. Wir runden unser Angebot für Sie ab: mit Spezialprodukten, wie zum Beispiel knusprig, aber schonend, gebackenen Leinsaat-Samen und individuellen Lösungen nach Ihren Anforderungen.

Grenzenlos vielfältig.

Wir haben das passende Trockenprodukt aus Früchten, Gemüse oder Getreide, das Ihrem Produkt die besondere Note verleiht.

Und das in der genau passenden Größe und Mischung.

Das ergibt nicht nur Sinn, sondern vor allem ein einzigartiges Genusserlebnis für Ihre Kunden – in Geschmack und Textur.

Wir beraten Sie gerne, worauf es bei der Wahl ankommt und welches Produkt in welcher Feinheit für Ihre Anwendung am besten geeignet ist.

Kontaktieren Sie uns

Ihre Idee ist unsere

Herausforderung!

Sie haben konkrete Vorstellungen zu einem neuen Produkt? Teilen Sie uns Ihre Wünsche mit, und wir machen uns, gemeinsam mit Ihnen, an die Entwicklung Ihrer individuellen Rezepturen und Mischungen. Mit unserem "Rundum-sorglos-Paket" - bestehend aus Produktentwicklung, Trocknen, Mahlen, Mischen, Backen und Konfektionieren - bieten wir Ihnen individuelle Komplettlösungen aus einer Hand.

Mehr als nur eine Frage des guten Geschmacks!

Unsere Produkte sind grundsätzlich GVO-frei und werden ohne Zusatz von Farb-, Aroma- oder Konservierungsstoffen mithilfe nachhaltiger und umweltbewusster Verfahren hergestellt und verpackt. Sie erhalten bei uns nahezu alle Erzeugnisse auf Wunsch glutenfrei, vegan, koscher, in Baby-Food- oder zertifizierter Bio-Qualität.